In today’s fast-paced industries, prototyping plays a critical role in turning creative concepts into tangible outcomes. By bridging the gap between ideas and production, it allows innovators to test, refine, and validate their designs before committing to full-scale production.

Through modern prototype design and advanced prototyping services, businesses can explore multiple iterations quickly and cost-effectively. Whether using traditional methods or a 3D print prototype, the ability to create functional models accelerates decision-making and reduces the risk of costly mistakes.

Ultimately, prototyping empowers startups, engineers, and established companies alike to bring products to life with confidence—making it one of the most valuable tools in modern innovation.

What Is Prototyping and Why It Matters

At its core, prototyping is the process of transforming an abstract idea into a physical or digital model that can be tested and refined. It acts as a bridge between creative concept and final product, giving teams the chance to identify design flaws, improve usability, and validate functionality before investing in full-scale production.

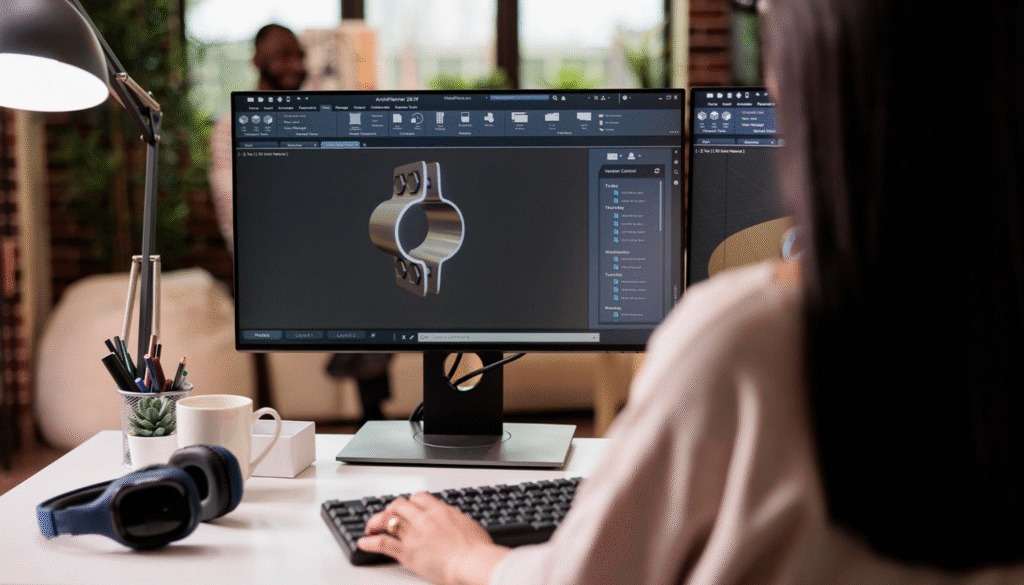

Modern prototype design goes beyond sketches and CAD files; it includes not only tangible models created through prototype manufacturing techniques such as CNC machining, injection molding, or a fast 3D print prototype, but also digital simulations and virtual prototypes that allow for early validation. These approaches enable businesses to gather feedback, test performance, and accelerate product development cycles.

For startups and established enterprises alike, working with professional prototyping services or trusted prototype manufacturing companies reduces risk and saves costs. By catching issues early, prototyping ensures that innovations move forward with confidence and efficiency, making it an essential step in today’s competitive product development landscape.

Types of Prototypes You Should Know About

One of the most important aspects of prototyping is understanding that not all prototypes serve the same purpose. Depending on the stage of development, businesses and innovators can rely on different forms of prototype design to validate ideas and guide decision-making.

- Concept prototypes are very early models, often simple sketches, mock-ups, or even rough 3D shapes. They are not meant for performance testing but help communicate ideas clearly to stakeholders.

- Functional prototypes go one step further, allowing teams to test usability and core features. These models are commonly produced through prototype manufacturing techniques like CNC machining or a quick 3D print prototype, enabling hands-on evaluation.

- High-fidelity prototypes resemble the final product in both appearance and performance. Often created by specialized prototype manufacturing companies or advanced prototyping services, they are essential for investor presentations, user testing, and pre-production validation.

By leveraging the right type of prototype at the right time, businesses reduce risk, save costs, and accelerate the path from idea to product.

How Prototyping Reduces Risk and Saves Money

Effective prototyping is more than just building early models—it is a strategy to minimize costly mistakes and accelerate decision-making. By creating tangible models through prototype design and prototype manufacturing, teams can test functionality, identify weak points, and correct flaws before full-scale production. This early validation helps avoid expensive design errors that might otherwise surface late in the process.

Modern prototyping services also make it possible to build quick iterations using methods like CNC machining or a 3D print prototype, giving innovators the flexibility to compare different options at low cost. This not only reduces financial risk but also speeds up the approval process for stakeholders and investors who want evidence before committing resources.

Whether working with startups or established enterprises, trusted prototype manufacturing companies ensure that innovations move forward with confidence, saving both time and money in today’s competitive product landscape.

Tools and Technologies Behind Prototyping

Modern prototyping uses a wide range of tools and technologies to help innovators turn ideas into testable, functional products. Each tool has its unique strengths, depending on whether the goal is concept validation, functional testing, or preparing for production.

- 3D Printing: One of the fastest and most cost-effective ways to create early models. A 3D print prototype allows teams to test shapes, geometries, and even assembly fit without the need for expensive tooling.

- CNC Machining: Essential when accuracy, strength, and real-world performance are required. CNC is widely used in prototype manufacturing for both metals and plastics, producing functional parts with tight tolerances.

- Virtual Prototyping and Digital Simulations: A risk-free method to test product performance digitally. By running stress tests, usability studies, and simulations, businesses can refine their prototype design before investing in physical models.

- Injection Molding for Prototypes: Known as rapid or bridge tooling, this process creates low-volume parts in production-grade materials. It’s often used by prototype manufacturing companies for consumer products and medical devices.

- Sheet Metal Prototyping: Ideal for enclosures, brackets, and structural parts. This method offers quick turnaround for functional metal prototypes that resemble end-use parts.

- Laser Cutting & Waterjet Cutting: Precise processes to quickly create 2D components from metal, wood, or plastic. These are popular in early prototyping services when flat parts or quick mock-ups are needed.

- Foam, Clay, or Wood Models: Still used in industrial design for concept prototypes, allowing teams to visualize scale and ergonomics in the earliest stages.

By combining these technologies—or using them through specialized prototype manufacturing companies—businesses reduce risk, save costs, and accelerate the journey from idea to product.

Prototyping in Action: Real-World Examples

The true value of prototyping is best seen in real-world applications, where innovative ideas are transformed into functional products across different industries.

- Medical Industry: In healthcare, precision and safety are critical. Through advanced prototype design and prototype manufacturing, companies develop surgical instruments, dental tools, and even implants that must meet strict standards. Using methods like CNC machining or a 3D print prototype, medical teams can validate ergonomics and functionality before large-scale production, reducing risks for patients.

- Automotive Industry: Car manufacturers and suppliers rely heavily on prototyping services to test engine components, body panels, and interior parts. Rapid prototype manufacturing companies enable them to check durability, aerodynamics, and fit, ensuring that final designs meet both performance and safety requirements.

- Startups and Entrepreneurs: For new ventures, prototyping is the fastest way to transform a concept into something tangible that can attract investors. Whether built through 3D print prototypes for early demos or CNC-machined parts for functional testing, prototypes help startups validate ideas quickly and secure funding.

These examples show how prototyping reduces risk, saves costs, and accelerates innovation, making it a cornerstone of modern product development.

Future of Prototyping: Where Innovation Is Heading

The future of prototyping is being reshaped by breakthroughs in artificial intelligence, sustainable materials, and the fusion of digital and physical workflows. These innovations are redefining how prototype design, prototype manufacturing, and prototyping services will operate in the coming decade.

- AI in Design and Simulation: According to McKinsey’s Future of Manufacturing 2024, integrating AI into CAD modeling and simulations is expected to shorten design cycles by up to 30%. This trend builds on findings from Nature Machine Intelligence (2022), which showed how generative AI can automatically create and optimize design iterations, while predictive algorithms enhance stress testing before physical prototype manufacturing.

- Smart and Sustainable Materials: Deloitte Insights 2024 – Sustainable Manufacturing reports that more than 40% of global manufacturers aim to adopt bio-based and recyclable polymers in their prototyping services by 2030. This aligns with research in Advanced Materials (2023), which highlights the development of high-performance composites and resins suitable for both 3D print prototypes and CNC machining.

- Hybrid Digital + Physical Prototyping: Gartner’s Emerging Tech Report 2024 predicts that by 2027, nearly 70% of prototype manufacturing companies will use digital twins to validate designs before building physical prototypes. This evolution is reinforced by studies in IEEE Access (2022), which documented the efficiency of linking virtual simulations with physical prototyping for faster and more accurate development.

Together, these advances point toward a smarter, greener, and more integrated era of prototyping, where businesses can innovate faster while meeting global demands for sustainability and precision.

Conclusion: Prototyping as the Foundation of Innovation

From concept sketches to fully functional models, prototyping is the foundation of modern innovation. It reduces risk, saves costs, and accelerates the journey from idea to market—empowering startups, engineers, and global enterprises alike to innovate with confidence. By combining prototype design, prototype manufacturing, and cutting-edge prototyping services, businesses can validate ideas and move forward faster than ever before.

At Netprocore, we simplify this process by offering end-to-end solutions, from 3D print prototypes to CNC machining and engineering support. Whether you need a quick model for testing or a high-fidelity prototype for investors, our team delivers precision, speed, and reliability.

Explore how Netprocore can bring your ideas to life—partner with us and take the next step toward smarter product development.

Frequently Asked Questions (FAQ)

Prototyping is the process of creating physical or digital models to test and refine ideas before full-scale production. It helps reduce risks, identify design flaws early, and accelerate time-to-market, making it an essential step in modern product development.

The most widely used methods include 3D print prototypes for quick and affordable models, CNC machining for precision parts, injection molding for low-volume production in real materials, and digital simulations for virtual testing.

By catching design issues early, prototyping services help companies avoid costly mistakes during mass production. Iterations are faster and cheaper, especially when using methods like 3D printing or CNC machining, ensuring smarter investment decisions.

- Sectors like medical devices, automotive, aerospace, consumer electronics, and startups all rely on prototype manufacturing companies. Prototyping enables them to validate functionality, improve usability, and present investor-ready models.

Netprocore offers end-to-end prototype design and prototype manufacturing solutions, including 3D printing, CNC machining, CAD engineering, and post-processing. Whether you need a quick demo model or a high-fidelity prototype, Netprocore delivers speed, accuracy, and reliability.