From Prototyping to Production

Professional 3D printing services have become a cornerstone of modern product development, offering businesses a faster and more cost-effective way to transform ideas into tangible results. Unlike traditional manufacturing, which often requires expensive tooling and long lead times, 3D printing enables rapid prototyping, design flexibility, and small-batch production with minimal waste.

Today, industries ranging from healthcare and automotive to consumer products and architecture rely on these innovative manufacturing methods to accelerate research, test custom parts, and bring new products to market faster. By leveraging advanced 3D printing materials and technologies such as FDM, SLA, and SLS, professional 3D printing services empower companies to reduce costs, shorten timelines, and stay ahead in highly competitive markets.

Why Businesses Choose 3D Printing Services

Companies across industries increasingly rely on professional 3D printing services because they deliver advantages that traditional manufacturing cannot match. One of the most important benefits is cost reduction. Since no expensive molds or tooling are required, businesses can prototype or produce small batches at a fraction of the cost, making innovation more accessible to startups and established enterprises alike.

Another major reason is faster product development. With rapid prototyping, engineers and designers can test multiple iterations in days instead of weeks, allowing them to refine designs and move to market much faster.

Finally, customized production and on-demand manufacturing make 3D printing services ideal for businesses that need flexibility. Whether it’s creating unique medical devices, automotive components, or consumer goods, 3D printing enables companies to produce tailor-made parts that meet exact specifications, without compromising on quality or efficiency.

3D Printing Services for Prototypes and Product Development

Professional 3D printing services play a critical role in product development, especially when it comes to prototyping. In competitive markets, speed is everything—being able to test an idea, make adjustments, and launch quickly often determines success. That’s why many businesses rely on 3D printing services for prototypes to validate concepts and improve designs before investing in full-scale production.

With rapid prototyping, engineers and designers can evaluate functionality, performance, and ergonomics in just a few days. This process not only shortens development cycles but also helps companies avoid costly mistakes by identifying design flaws early.

Moreover, professional 3D printing services enable iterative testing. A product can go through multiple design versions without the high costs associated with traditional tooling. As a result, businesses can bring more reliable, market-ready products to customers faster, while maintaining full control over design flexibility and production costs.

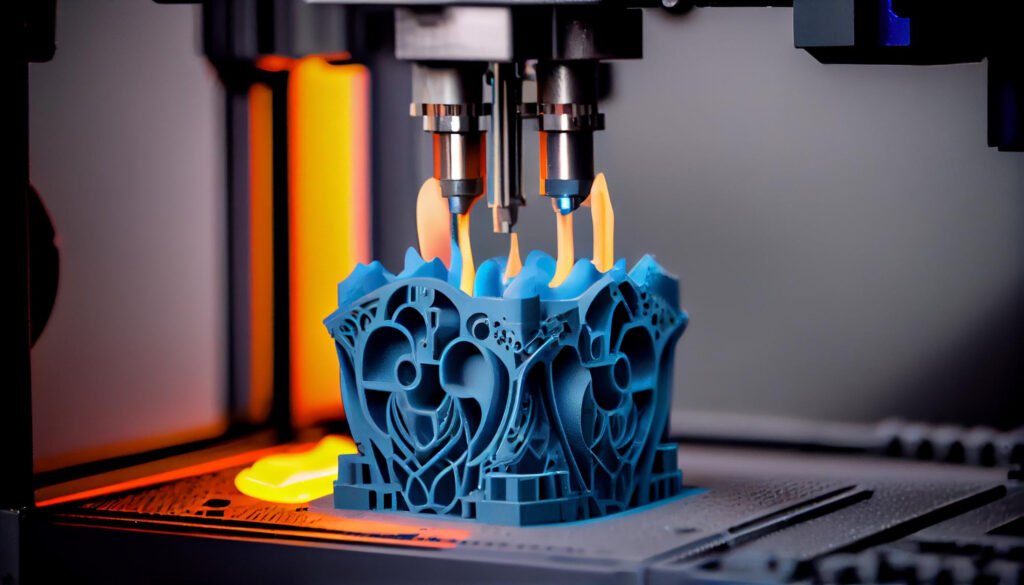

3D Printing Technologies: FDM vs SLA vs SLS

One of the most common questions businesses ask when exploring 3D printing services is which technology best suits their needs. The debate of FDM vs SLA 3D printing highlights the different strengths of each process. FDM (Fused Deposition Modeling) is cost-effective, ideal for creating functional prototypes and larger components using materials such as PLA or ABS. It’s the go-to choice when strength and affordability are top priorities.

On the other hand, SLA (Stereolithography) produces high-resolution parts with exceptional surface quality. It is widely used for applications that demand precision, such as dental models, medical devices, or intricate consumer products. SLA is preferred when detail and smooth finishes are essential.

The third major option is SLS (Selective Laser Sintering), which uses nylon powders to build durable and complex geometries without the need for support structures. This makes it an excellent solution for industrial applications where strength and flexibility matter.

By offering FDM, SLA, and SLS technologies, professional 3D printing services give companies the flexibility to choose the right method for their specific product requirements.

3D Printing Materials Explained: PLA, ABS, PETG, Resin, Nylon

A major strength of professional 3D printing services lies in the wide variety of materials available, each offering unique advantages for different applications. Choosing the right option from the range of 3D printing materials ensures the best balance between durability, cost, and performance.

PLA is one of the most popular choices, valued for being affordable, biodegradable, and ideal for concept models or educational projects. ABS, on the other hand, is stronger and more heat-resistant, making it suitable for functional prototypes and automotive parts.

PETG combines the ease of printing with higher toughness and chemical resistance, often used for industrial components that require strength and flexibility. Resin materials deliver ultra-high precision and smooth finishes, which are perfect for dental models, medical tools, and finely detailed consumer products.

Finally, Nylon (SLS) is a high-performance choice for engineering-grade parts, offering excellent mechanical strength, impact resistance, and flexibility—ideal for complex geometries in demanding industries.

By offering such a diverse set of 3D printing materials, professional 3D printing services make it possible to tailor every project to the exact requirements of the client.

Key Advantages of Using 3D Printing Services

Professional 3D printing services provide businesses with a powerful set of advantages that traditional manufacturing methods cannot easily match. The first is speed to market. With rapid prototyping, companies can move from concept to finished part in a matter of days, allowing faster product launches.

Another key benefit is design freedom. Complex shapes, lightweight structures, and custom features can be produced without the limitations of traditional tooling. Combined with cost efficiency, this makes 3D printing services an attractive option for startups and enterprises alike.

Finally, the repeatability of the process ensures that once a design is finalized, it can be reproduced consistently at scale. This flexibility enables true on-demand production, helping businesses reduce waste, lower inventory, and stay competitive in fast-moving markets.

Industries Benefiting from 3D Printing

Professional 3D printing services are transforming a wide range of industries by making innovation faster, more affordable, and more precise. In medical 3D printing, custom surgical guides, dental models, and prosthetics improve patient care and reduce lead times. The automotive industry uses 3D printed prototypes to test interior parts, engine components, and lightweight structures with minimal cost.

In architecture, firms rely on 3D printing services to create accurate scale models and complex design elements, while consumer product companies leverage the technology for small-batch production and iterative design. Education and R&D institutions also benefit by using 3D printing to support hands-on learning and rapid experimentation.

Even startups increasingly depend on professional 3D printing services to validate ideas quickly, build prototypes affordably, and attract investors with tangible proof-of-concept models.

How to Choose the Best 3D Printing Company in Canada

Selecting the best 3D printing company in Canada requires looking beyond basic pricing and capabilities. The first factor to consider is experience. A provider with a proven track record in delivering high-quality 3D printing services for multiple industries is more likely to meet demanding project requirements.

Equally important is the quality of materials offered. From PLA and ABS to engineering-grade resins and nylon, the right partner should provide reliable 3D printing materials that ensure durability and precision.

Businesses should also evaluate turnaround times, since speed is often critical in product development. Finally, strong engineering support adds value by helping optimize designs for manufacturability and cost efficiency. By combining these factors, companies can confidently choose the right partner and gain a competitive edge in the Canadian market.

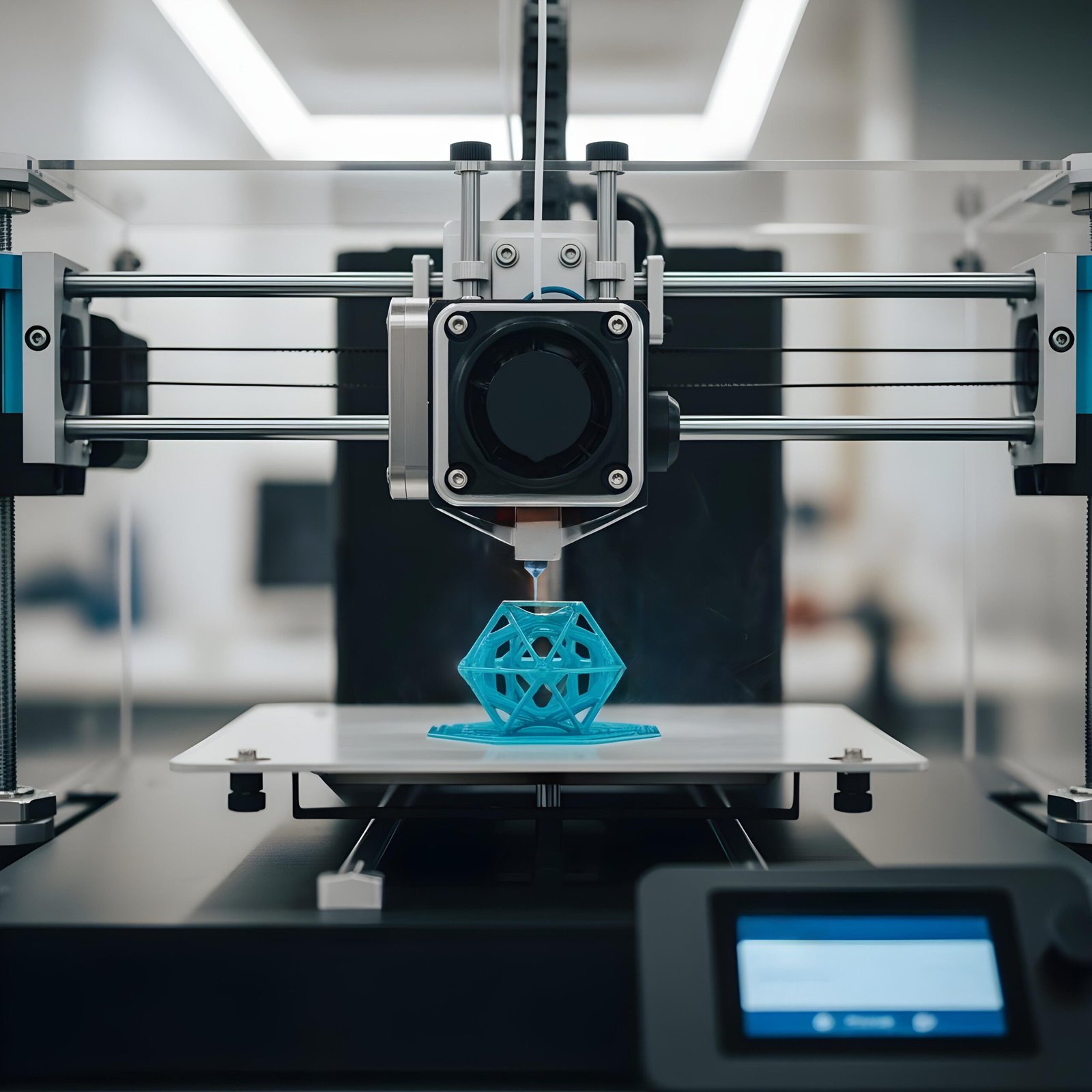

End-to-End 3D Printing & Prototyping Services

At Netprocore, we provide comprehensive 3D printing services designed to support businesses at every stage of product development. Our advanced 3D printing solutions include FDM, SLA, and SLS technologies, giving clients the flexibility to choose between cost-effective functional prototypes, ultra-precise resin parts, or durable nylon components. This versatility allows us to deliver everything from early design models to production-ready parts with unmatched speed and accuracy.

We also support a wide range of 3D printing materials to meet diverse project needs:

- PLA, ABS, PETG, TPU

- Resin (for ultra-precise parts)

- Nylon (SLS)

- Carbon-filled and glass-reinforced filaments

Beyond printing, we also offer CNC machining for high-precision metal and plastic parts, as well as rapid prototyping to accelerate time-to-market. Our CAD design & engineering support ensures your concepts are optimized for manufacturability, while our post-processing & assembly services—such as sanding, painting, and sterilization—deliver finished parts that are ready for immediate use.

With Netprocore’s end-to-end approach, you gain a trusted partner that combines innovation, expertise, and reliability. Upload your design today and receive a detailed quote within 24 hours—your ideas deserve to be brought to life without delay.

Frequently Asked Questions

Industries such as healthcare, automotive, consumer products, architecture, education, and startups benefit from professional 3D printing services. These sectors use the technology for rapid prototyping, product testing, and small-batch production.

FDM (Fused Deposition Modeling) is cost-effective and ideal for functional prototypes and larger parts. SLA (Stereolithography) offers high-resolution details and smooth finishes, making it perfect for medical, dental, and precision consumer products.

The most popular 3D printing materials include PLA, ABS, PETG, resin, and nylon (SLS). Each has unique benefits: PLA is affordable and eco-friendly, ABS is strong and heat-resistant, PETG offers toughness and chemical resistance, resin delivers precision, and nylon provides durability and flexibility.

Look for a provider with proven experience, high-quality materials, fast turnaround times, and reliable engineering support. These factors ensure you partner with the best 3D printing company in Canada for your project needs.

Yes. In addition to professional 3D printing services, Netprocore offers CNC machining, rapid prototyping, CAD design & engineering support, and post-processing & assembly to deliver end-to-end product development solutions.