Parts and Applications

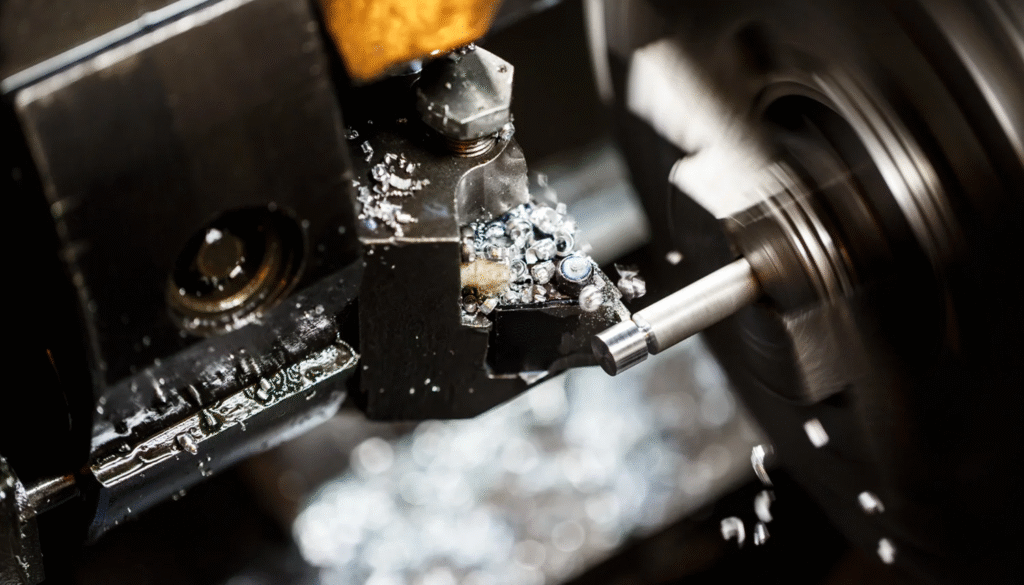

In today’s competitive manufacturing landscape, professional CNC machining services have become essential for businesses seeking accuracy, speed, and reliability. Unlike traditional methods, CNC technology allows for the production of highly precise CNC machining parts, whether they are metal components for automotive engines or plastic parts for consumer products.

The value of CNC machining services lies in their ability to deliver consistent quality at scale while reducing costs and lead times. From medical devices to aerospace engineering, companies across diverse sectors rely on these advanced capabilities to bring designs to life with exceptional precision. As industries continue to demand innovation and efficiency, CNC machining stands at the center of modern product development and manufacturing.

What Is CNC Machining and How Does It Work?

At its core, CNC machining refers to the use of computer numerical control systems to automate cutting, milling, drilling, and turning operations. Instead of relying on manual labor, the process uses advanced software and programmed instructions to guide machinery with exceptional accuracy. This enables manufacturers to produce complex shapes and detailed parts that would be nearly impossible with traditional methods.

Professional CNC machining services integrate digital design files with CAM programming, where CAD models are converted into G-code toolpaths that the machine can execute. Once the instructions are set, CNC equipment shapes raw materials into precise, finished products. The result is precision manufacturing that ensures tight tolerances, repeatability, and reduced human error.

Because of its speed, flexibility, and efficiency, CNC machining has become the backbone of modern industries, powering everything from rapid prototypes to large-scale production runs.

Types of CNC Machining Services and Their Applications

Professional CNC machining services include a variety of processes designed to meet different production needs. Among the most common CNC services is CNC milling, which uses rotary cutters to remove material and create complex geometries or detailed surface features. It is ideal for precision parts with intricate designs.

Another widely used method is CNC turning, where the workpiece rotates while cutting tools shape it into cylindrical or symmetrical components. This process is essential in industries that require shafts, bushings, or threaded parts.

For more advanced projects, multi-axis machining provides greater flexibility. By moving the tool and workpiece along multiple axes, manufacturers can produce highly complex and precise components in a single setup, reducing time and improving accuracy.

Together, these CNC services form the backbone of modern manufacturing, enabling companies to choose the right process for both prototypes and large-scale production.

CNC Machining Materials: Metal and Plastic Parts

One of the greatest strengths of professional CNC machining services is the ability to work with a wide variety of materials, from durable metals to versatile plastics. When it comes to CNC machining metal parts, options such as aluminum, steel, and brass are widely used for their strength, heat resistance, and durability. Aluminum is ideal for lightweight components, steel offers excellent toughness for structural parts, and brass is preferred for precision fittings and corrosion resistance.

On the other hand, CNC machining plastic parts provide flexibility, cost-effectiveness, and excellent performance in applications where metals may not be necessary. Materials like ABS are valued for their impact resistance, nylon is known for wear resistance and low friction, and POM (Delrin) is commonly chosen for high-precision engineering plastics.

By offering both CNC machining metal parts and CNC machining plastic parts, professional CNC machining services empower businesses to select the right material for each application—whether for prototypes, functional testing, or full-scale production.

Feature / Material | CNC Machining Metal Parts | CNC Machining Plastic Parts |

Common Materials | Aluminum, Steel, Brass | ABS, Nylon, POM (Delrin) |

Advantages | High strength and durability, heat resistance, ideal for heavy-load applications | Lightweight, cost-effective, easy to machine, flexible for design |

Applications | Structural components, automotive engine parts, precision fittings, aerospace equipment | Consumer products, electronic housings, rapid prototypes, lightweight tools |

Limitations | Heavier weight, higher cost, more challenging machining | Lower mechanical and thermal resistance compared to metals |

Best Suited For | Mass production of industrial parts and high-stress applications | Prototyping, low-volume runs, complex geometries, and lightweight parts |

Advantages of CNC Machining Services for Modern Manufacturing

Modern industries demand efficiency, accuracy, and reliability — and this is exactly what professional CNC machining services deliver. One of the most significant advantages is high precision, allowing manufacturers to achieve tight tolerances that ensure every part fits perfectly. This level of accuracy is critical in fields such as aerospace, automotive, and medical devices.

Another key benefit is speed to market. With automated processes, companies can move from design to finished components quickly, reducing development cycles and staying ahead of competitors. At the same time, cost reduction is achieved by minimizing human error, reducing material waste, and streamlining production.

Finally, repeatability guarantees that once a prototype is perfected, the same part can be reproduced consistently at scale. Together, these advantages make CNC machining services the backbone of modern manufacturing, supporting businesses in delivering innovation with confidence.

Industries That Rely on CNC Machining Services

Professional CNC machining services are the backbone of many modern industries, delivering precision, reliability, and scalability. Companies across sectors rely on these solutions to create high-quality components that meet demanding standards. Key industries include:

- Automotive – production of engine parts, custom fixtures, and interior components.

- Aerospace – lightweight structural elements and high-tolerance precision fittings.

- Medical – surgical tools, implants, and prototypes for advanced devices.

- Consumer Products – housings, durable plastic parts, and small-batch production runs.

- R&D and Startups – rapid prototyping and iterative testing for innovation.

By serving such a diverse range of fields, CNC machining services empower both established enterprises and agile innovators to turn designs into functional, market-ready products.

CNC Machining Parts: From Prototypes to Production

One of the biggest advantages of professional CNC machining services is their ability to support every stage of product development, from early ideas to large-scale manufacturing. In the prototyping phase, CNC machining parts allow engineers to quickly test form, fit, and functionality with high accuracy. This makes it easier to refine designs before investing in full production.

When it comes to mass production, the same CNC machining services ensure consistency and repeatability, producing hundreds or thousands of identical precision components that meet strict quality standards. Whether for rapid prototypes or production-ready runs, CNC machining parts give businesses the flexibility to innovate quickly while maintaining efficiency and reliability.

How CNC Machining Services Compare to Other Manufacturing Methods

Professional CNC machining services are often compared with both traditional machining and modern 3D printing. Each method has its strengths, but CNC stands out for its balance of precision, material versatility, and scalability.

Compared to traditional machining, CNC machining services reduce human error by relying on computer-controlled processes. This allows for higher consistency, tighter tolerances, and faster turnaround times while still accommodating both metal and plastic parts.

When compared to 3D printing, CNC machining offers superior strength and surface finish, making it ideal for functional parts and end-use applications. While 3D printing is excellent for rapid prototyping and complex geometries, it often lacks the durability and material range of CNC.

Ultimately, CNC machining services provide the reliability and efficiency required for industries that demand precision manufacturing, bridging the gap between flexibility and production-ready quality.

How to Choose the Right CNC Machining Partner

Selecting the right partner for professional CNC machining services can make the difference between a successful project and costly delays. The first factor to consider is experience. A provider with proven expertise in delivering high-quality CNC services across multiple industries is more likely to handle complex requirements.

Equally important is the quality of parts. Whether producing metal or plastic components, the right partner should maintain tight tolerances and consistent standards. Turnaround time also matters; a reliable company must deliver projects on schedule to keep your production moving.

Finally, strong engineering support ensures that designs are optimized for manufacturability and cost-efficiency. By evaluating these criteria, businesses can confidently choose a CNC partner that provides both precision and reliability.

Conclusion: The Future of CNC Machining Services

The future of CNC machining services lies in greater precision, smarter automation, and faster delivery for every industry. As demand for high-quality parts continues to grow, businesses need partners they can trust. Netprocore provides end-to-end CNC machining services tailored to your needs—upload your design today and get a custom quote.

Check our other article : Professional 3D Printing Services in Canada