3D Printing in the Medical Industry: From CAD to Approved Medical Components

Bring your idea to life.

Upload your file today and get a precise manufacturing quote in less than 24 hours.

Recent Posts

Over the past decade, medical 3D printing has evolved from a niche research tool into a practical technology used across hospitals and medical device companies. It enables surgeons and engineers to create highly customized solutions directly from digital data, transforming how patient care is planned and delivered.

A major driver of this shift is the growing use of anatomical models made from CT or MRI scans. These models help surgeons understand patient-specific anatomy before entering the operating room. Behind them is the specialized work of medical CAD design, which converts imaging data into precise printable geometries. As healthcare additive manufacturing advances, 3D printing is also producing functional components, surgical tools, and even early implant prototypes.

Of course, moving from CAD to a clinically approved part requires strict attention to safety and regulation. Materials, design choices, and testing strategies all influence whether a prototype can meet FDA-related prototyping considerations and move toward real clinical use.

In the sections ahead, we break down how medical 3D printing works in practice and what it takes to turn a digital idea into an approved medical component.

How 3D Printing Is Reshaping Modern Medicine

Over the last several years, medical 3D printing has moved from a promising experimental tool to a practical, everyday resource across hospitals, research centers, and medical device companies. What makes it so transformative is its ability to create customized parts directly from digital data, allowing treatments and interventions to be shaped around the unique needs of each patient. Instead of relying on generic components or time-consuming fabrication methods, clinicians and engineers can now turn digital concepts into physical solutions with unprecedented speed and precision.

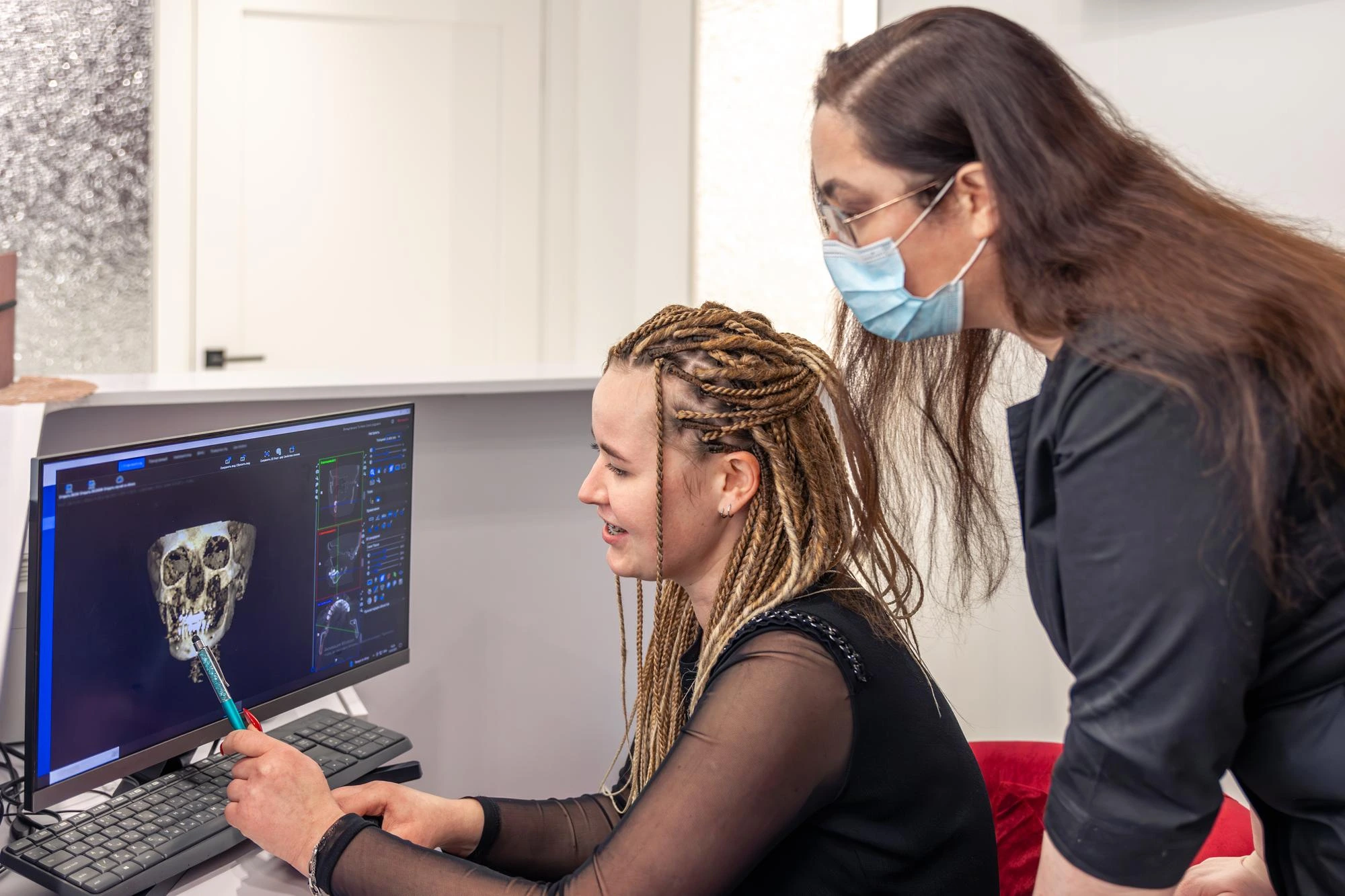

One of the clearest examples of this shift is the growing use of anatomical models created from patient CT or MRI scans. These life-like replicas help surgeons study complex structures before entering the operating room, improving accuracy and reducing surgical risk. Behind these models is the sophisticated work of medical CAD design, where imaging data is converted into detailed, printable geometries tailored for clinical use.

Beyond models, the rise of healthcare additive manufacturing is opening the door to functional surgical tools, patient-specific implants, custom prosthetics, and a new generation of medical components. As this technology becomes more integrated into regulated workflows, teams must also consider FDA-related prototyping considerations, from material safety to documentation and traceability.

Medical 3D printing is not just another tool. It is reshaping how healthcare thinks about innovation, personalization, and the speed at which life-changing solutions can reach real patients. In the next sections, we’ll explore how this digital-to-physical process works and why it is becoming essential in modern medicine.

Check our other article : Professional 3D Printing Services in Canada

From CT Scan to CAD: Turning Patient Data Into Printable Models

The journey of medical 3D printing often begins long before anything is printed. It starts inside the CT or MRI scanner, where raw patient data is captured and later transformed into a detailed 3D model. This step is far more complex than simply importing images into a software tool. It requires medical knowledge, engineering precision, and a deep understanding of how anatomy behaves when converted into digital geometry.

Once imaging data is collected, specialists use advanced medical CAD design tools to separate the anatomical structures of interest — a process known as segmentation. Each slice of the scan must be carefully analyzed to ensure the final 3D reconstruction is accurate enough for clinical use. This is especially important when creating anatomical models for surgical planning, where even a small error in geometry can influence how a surgeon approaches a complex procedure.

After segmentation, engineers refine the digital mesh, smoothing surfaces, removing noise, correcting gaps, and preparing the file for printing. At this stage, teams must also consider material properties, print resolution, and the intended clinical application. For cases that may eventually move into real medical device development, early modeling decisions influence how easily the design can align with FDA-related prototyping considerations, including traceability and documentation.

What may look simple on the screen is the result of a highly specialized workflow that blends imaging science, engineering, and clinical awareness. By the time a file is ready for printing, it represents not just data, but a carefully engineered bridge between the patient’s anatomy and a physical model that can guide real medical decisions.

From Prototype to Production – We've Got You Covered

No matter where you are in your product journey, our team handles every step, design optimization, 3D printing, CNC machining, and finishing. Start Your Project →

The Power of Anatomical Models: When Precision Saves Lives

Among all the applications of medical 3D printing, few have had as direct and immediate an impact as anatomical models. These models give surgeons something they never had before: a patient-specific, tangible representation of the anatomy they are about to operate on. Instead of relying solely on 2D scans or mental reconstruction, clinicians can hold the problem in their hands, rotate it, study it, and plan every step of a complex intervention with far greater clarity.

Real-world examples show how powerful this can be. In cardiac surgery, doctors use anatomical models of the heart to analyze congenital defects or valve abnormalities before making a single incision. Orthopedic teams rely on printed bone models to map out screw trajectories or rehearse trauma reconstructions. In oncology, tumor models created through medical CAD design allow surgeons to assess margins and choose the safest approach. Even medical students and residents benefit from this technology, using physical models to understand rare anatomical variations that would be impossible to study otherwise.

As hospitals expand their use of healthcare additive manufacturing, these models are becoming standard tools rather than experimental extras. Their accuracy helps reduce operating time, minimize risk, and improve communication between surgeons and patients. And when a model is part of a device development workflow, it may also influence early design decisions that need to align with FDA-related prototyping considerations.

Anatomical models demonstrate the true promise of medical 3D printing: precision that directly improves patient outcomes. They turn data into understanding, and understanding into safer, more confident care.

How Healthcare Additive Manufacturing Produces Real Medical Components

As powerful as medical 3D printing is for creating anatomical models, its real breakthrough comes when the technology is used to produce functional medical components. Today, hospitals and device manufacturers rely on healthcare additive manufacturing to create implants, surgical tools, and customized prosthetic parts that meet demanding clinical requirements.

Patient-Specific Implants and Surgical Tools

Using advanced medical CAD design, engineers can turn CT or MRI data into patient-specific implants with exceptional accuracy. Titanium cranial plates, orthopedic implants, and customized cutting guides are now routinely produced with additive manufacturing. These devices often outperform traditional, standardized components because they are shaped to match the exact anatomy of each patient.

Prosthetics and Functional Medical Parts

3D printing has also transformed prosthetics by enabling lighter, more affordable, and personalized limb replacements. Beyond prosthetics, functional surgical instruments and ergonomic handles can be printed rapidly and adapted to specific clinical workflows.

Producing real medical components, however, requires strict adherence to FDA-related prototyping considerations. Material safety, sterility, documentation, and traceability all influence whether a printed component can move from concept to approved clinical use.

Healthcare additive manufacturing has moved far beyond simple models. It is now a practical and reliable pathway for creating high-performance medical devices that directly support patient treatment.

What Makes a Medical Part “Approved”? Understanding FDA and CE Requirements

As exciting as medical 3D printing is, no part can be used in a clinical setting until it meets the strict expectations of regulatory bodies such as the FDA in the United States and CE authorities in Europe. These organizations are responsible for ensuring that any printed component—whether it is a surgical guide, a prosthetic element, or a patient-specific implant—can perform safely and consistently. For many teams, this is where innovation meets a complex layer of paperwork, testing, and controlled processes.

One of the biggest challenges in navigating approval is understanding FDA-related prototyping considerations. Early design choices, including the materials selected, the way the CAD file is prepared, and the method of printing, all influence how smoothly a project can move toward regulatory acceptance. Authorities want to see clear documentation at every step: how the part was designed, who handled it, what materials were used, and how the printing and post-processing were controlled.

Material selection is especially important. Regulators expect proof that the material is biocompatible, stable, and safe for use inside the human body or during a surgical procedure. Equally critical is traceability—the ability to track each part back to its source data, CAD version, manufacturing parameters, and operator. And finally, rigorous mechanical and sterilization testing ensures that printed medical components can survive real clinical environments without unexpected failure.

In simple terms, a medical part becomes “approved” not just because it is well-designed, but because every decision surrounding its creation can be traced, tested, and trusted. That combination of engineering discipline and regulatory clarity is what separates a prototype from a true medical device.

Your

Prototype,

Perfected

Turn early concepts into flawless, test-ready models. Our experts refine geometry, materials, and tolerances to make sure your design performs as intended.

From CAD to Operating Room: The Practical Workflow for a Printable Medical Device

Turning a digital idea into a clinically usable device requires a workflow that blends engineering precision with medical safety. The process begins with imaging and medical CAD design, where CT or MRI data is transformed into a detailed digital model. Once validated, the model is prepared for printing using parameters that match the device’s intended performance—strength, flexibility, surface finish, sterilization compatibility, and more.

After printing, each component undergoes a series of validation steps. Dimensional accuracy is checked against the CAD file, surface quality is inspected, and mechanical behavior is tested if the part will experience load inside the body. These steps are essential not only for quality control but also for meeting FDA-related prototyping considerations and CE requirements. Functional guides or tools may go through rehearsal testing with surgeons, while implants require biocompatibility and sterilization assessments.

When all tests are passed, the device can move into clinical use, whether that means supporting a surgical procedure or being implanted in a patient. At this point, the value of medical 3D printing becomes fully visible: faster production, better personalization, and clearer surgical planning. As healthcare additive manufacturing becomes more integrated into hospitals, this workflow is rapidly becoming a standard path from concept to patient care.

For teams seeking to develop reliable, compliant medical components, Netprocore can support every stage—from CAD preparation to validation and documentation—ensuring your printed device is ready for safe and confident use in the operating room.